Sustainable Construction

Objective

Deliver low carbon, resource efficient, whole life solutions

Goals

Collaborate across our value chain to promote sustainable construction

Provide industry leading guidance and solutions that optimise whole life performance

Innovate low carbon, sustainable products, services and solutions

“As an industry we can work together to reduce our carbon emissions through the use of new and improved strategies, processes and materials that will drive us all forward towards the target of net zero.”

Emma Hines, sustainability director

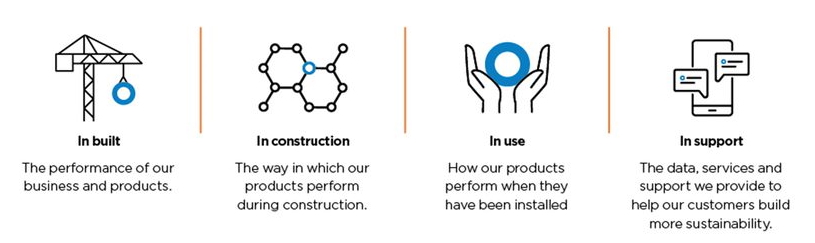

The products, services and tools we provide are of significant benefit to our customers and clients when it comes to designing and building more sustainably. We can deliver even more sustainable benefits when we are engaged early in advance of a project commencing. We are committed to delivering value to our customers and clients through application of our four ‘ins’ model, helping them take a whole life cycle approach to meeting the challenge of creating a more sustainable built environment.

Highlights

Our approach to solutions

To help customers create a more sustainable built environment we focus our approach across four areas:

In built

Continuously improving the sustainability performance of our business and of our products is a key element of sustainable construction. We do this by ensuring our raw materials are responsibly sourced, protecting the environment and enhancing biodiversity through excellent site stewardship, reducing carbon, water and waste, increasing recycled content and improving transport efficiency.

In construction

Whether it is being safer, faster, more flexible or reducing waste, the way in which our products perform during construction is an important element of our commitment to sustainability. We continue to research and deliver new innovative products to assist our customers’ projects.

In use

How our products perform once they have been installed is a crucial part of their life cycle and can have a profound impact on the sustainability of a building or infrastructure asset. Our solutions can improve sustainability during the in-use phase by enhancing durability, reducing maintenance, and delivering energy and carbon savings. Designing products so that they can be efficiently re-used at the end of their current life can also contribute towards a circular economy.

In support

The information, services and tools we provide are of significant benefit to customers when it comes to designing and building more sustainably. We can deliver even more sustainable benefits when we are engaged early, in advance of a project commencing.

Low carbon concrete collaboration

In 2022, Skanska, alongside Tarmac, the National Composites Centre, Basalt Technologies and National Highways, has carried out a trial on a low carbon reinforced concrete solution. The results show that the solution has led to a reduction of more than 50% in carbon. It has also proven to be equally resilient as conventional reinforced concrete using steel. Skanska published a report on the trials conducted on its M42 junction 6 project for National Highways and is now working on the next phase of the project, with the aim to rollout the low carbon solutions across the UK’s strategic road network.

Tarmac also collaborated with Align to trial an innovative low carbon concrete solution. We have a common goal of working towards net zero carbon construction. This new concrete, which is only recently available following extensive laboratory design, offers the potential to help achieve this objective. The new low carbon concrete has a carbon footprint that gives a 62% reduction in CO2 per cubic metre of concrete, compared to a standard CEM I concrete.

Tarmac Guide to Sustainable Road Building

As part of our sustainability strategy, we launched an online framework designed to support those involved in specifying and maintaining the UK’s crucial network of roads and highways. Tarmac’s ‘Guide to Sustainable Road Building’ offers advice including using lower carbon materials, reducing waste and incorporating recycled materials to create more sustainable roads. We have kept this online framework updated in 2022 with information on new trials and initiatives such as biogenic asphalt technology and our switch to warm mix asphalt.

Leading change to low temperature asphalt

In 2022, Tarmac announced it would now be supplying only warm mix asphalts for delivered base and binder courses and all surface course materials except for modified binder materials and HRA with a stone content mix of 35% or lower. In doing so, Tarmac became the first in the industry to phase out traditional hot mix asphalt for highways projects.

Warm mix temperature asphalt technology has the potential to reduce the embodied carbon of asphalt by up to 15% compared to conventional hot mixes. The lower temperature material also enables road projects to be delivered faster than when using traditional materials. The asphalt is delivered cooler than hot mixes, and therefore takes less time to reach trafficking temperature. This means that the road can be opened up to 90 minutes earlier to traffic, reducing disruption for road users.

This change to warm mix asphalt is expected to save around 21,000 tonnes of CO2 per year.

Over 1.9 million tonnes

warm mix asphalt produced in 2022

Innovative construction solutions

Combining road innovations - For a project with Lancashire Council we took a multi-faceted approach using recycled materials such as recycled asphalt planings (RAP) and rubber modified asphalt, combined with our warm mix binder technology to help them introduce more sustainable materials into their standard road maintenance activities.

Hydrogen lime kiln trial - Tarmac has revolutionised the way high-quality lime can be manufactured in the UK using hydrogen technology as part of a world-first net-zero trial. The trial, based at our lime site at Tunstead, is the culmination of a project funded by BEIS (Department for Business, Energy and Industrial Strategy)*, which has demonstrated the potential to use hydrogen as a viable alternative to natural gas for the commercial-scale production of lime.

*Now the Department for Energy Security and Net Zero (DESNZ)

Biogenic asphalt – in 2022, 530 tonnes of Tarmac’s biogenic asphalt was supplied to a project in Birmingham along with 630 tonnes of Ultilayer surface course. Using a biogenic asphalt binder course instead of the original warm mix asphalt binder course saved around 6.5 kg CO2 per tonne of asphalt, or 3.45 tonnes of CO2 in total.

Carbon footprints

Understanding the embodied carbon of products is the first part of the journey towards understanding the whole-life emissions of a project. For all our products we can provide product-specific carbon footprint information. Our carbon calculator has been created in accordance with the methodologies set out in PAS 2050:2011, ‘Specification for the assessment of the life cycle greenhouse gas emissions of goods and services’, and the Asphalt Pavement Embodied Carbon Tool (asPECT v3.0).

Calculating the CO2 footprint for a product not only provides a clear understanding of the products that are being used, but also allows for carbon to be managed in the supply chain. It is also possible to compare alternative products and services, actively seek lower carbon alternatives and understand the impact of using recycled and secondary materials.

Tarmac is committed to helping our clients meet their decarbonisation objectives by managing and reducing the carbon footprint of our operations and products. We are increasingly delivering low carbon materials, responding to carbon-related enquiries and supporting customers to select the lowest carbon option for their projects, which helps them to achieve their carbon targets. In 2022, we delivered over 1,500 carbon footprint calculations.

We’re serious about managing and reducing the carbon footprint of our products and helping our customers to do the same. We take a whole-life approach, which considers the impact of our products over their entire life cycle, from extraction, production and transport to performance in use, maintenance and final recycling or re-use.

carbon footprint calculations delivered

Looking forward

As a leading supplier of sustainable construction materials, we know we have a key role in the creation of a sustainable built environment. In 2023, we will continue to collaborate across the value chain to promote sustainable construction and provide industry-leading guidance. We will help our customers and clients understand how to use our products to build more sustainably through local and national events, including our third annual Supplier Sustainability Week.

In 2023, Tarmac will launch its roadmap to net zero. This will detail the levers we will use to achieve net zero by 2050 and assist our stakeholders to understand the ways in which Tarmac will reach this goal. As part of this roadmap, we will continue to focus on sustainable construction solutions that offer low carbon, efficient whole-life benefits. These include lower carbon Portland Limestone Cement and Concretes and the next generation of porous asphalt, to help mitigate against risks around climate, flooding and drought events with sustainable drainage solutions.